Home / Tungsten Carbide / Tungsten Carbide Rods / Solid Blank Round Bars / Tungsten Carbide Solid Metric Rough Ground Carbide Tool Rod Blank for Bulk Metal Processing

Tungsten Steel Solid Metric Rough Ground Carbide Tool Rod Blank for Bulk Metal Processing

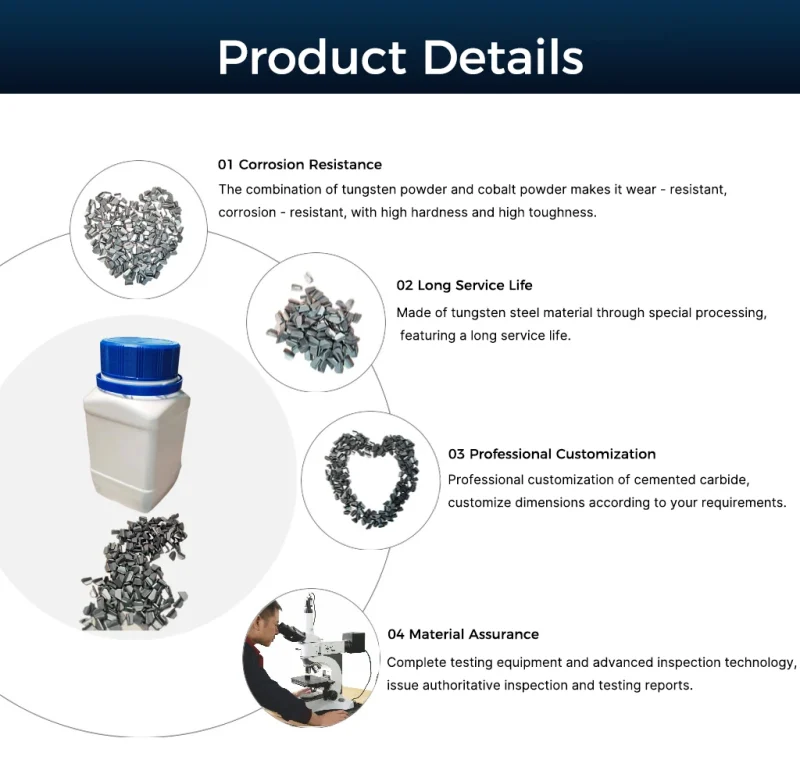

Our tungsten carbide solid metric rough - ground carbide tool rod blanks are engineered specifically for bulk metal processing. These blanks serve as the ideal starting point for fabricating high - performance carbide tools. Their rough - ground surface is primed for further precision machining, allowing manufacturers to customize the rods according to their exact requirements. Made from top - grade tungsten carbide, they offer exceptional hardness and wear resistance, ensuring long - lasting performance under the intense demands of large - scale metalworking operations. Whether for turning, milling, or drilling, these rod blanks are a reliable choice for efficient and high - quality tool production.

Precision Ground Tungsten Carbide Rods

Our solid carbide rods, featuring standard, rough, and fine grinding options, are engineered for superior performance. As a leading manufacturer, Suntera New Materials guarantees quality and precision in every product. We invite custom orders, ensuring your specific needs are met with our direct manufacturing and quality assurance.

Select Suntera for reliable, high-quality carbide solutions tailored to your project requirements.

Fixed Length Solid Round Rod Specification Sheet

| Diameter (mm) | Rough Tolerance | Ground Tolerance | Length (mm) | Tolerance | Chamfer X45° Tolerance ±0.1mm |

| 3.2 | -0.05/+0.15 | h6/h5 | 40 | 0/+1% x Length, Min +0.5mm | 0.4 |

| 3.2 | -0.05/+0.15 | h6/h5 | 50 | 0/+1% x Length, Min +0.5mm | 0.4 |

| 4.2 | -0.05/+0.15 | h6/h5 | 40 | 0/+1% x Length, Min +0.5mm | 0.4 |

| 4.2 | -0.05/+0.15 | h6/h5 | 50 | 0/+1% x Length, Min +0.5mm | 0.4 |

| 4.2 | -0.05/+0.15 | h6/h5 | 75 | 0/+1% x Length, Min +0.5mm | 0.4 |

| 5.2 | -0.05/+0.15 | h6/h5 | 50 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 5.2 | -0.05/+0.15 | h6/h5 | 55 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 5.2 | -0.05/+0.15 | h6/h5 | 60 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 5.2 | -0.05/+0.15 | h6/h5 | 70 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 5.2 | -0.05/+0.15 | h6/h5 | 80 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 6.2 | -0.05/+0.15 | h6/h5 | 50 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 6.2 | -0.05/+0.15 | h6/h5 | 60 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 6.2 | -0.05/+0.15 | h6/h5 | 75 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 6.2 | -0.05/+0.15 | h6/h5 | 100 | 0/+1% x Length, Min +0.5mm | 0.5 |

| 7.2 | -0.05/+0.15 | h6/h5 | 55 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 7.2 | -0.05/+0.15 | h6/h5 | 60 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 8.2 | -0.05/+0.15 | h6/h5 | 60 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 8.2 | -0.05/+0.15 | h6/h5 | 75 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 8.2 | -0.05/+0.15 | h6/h5 | 80 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 8.2 | -0.05/+0.15 | h6/h5 | 90 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 8.2 | -0.05/+0.15 | h6/h5 | 100 | 0/+1% x Length, Min +0.5mm | 0.6 |

| 8.2 | -0.05/+0.15 | h6/h5 | 150 | 0/+1% x Length, Min +0.5mm | 0.6 |